In today's competitive landscape, simply fixing the problem isn't enough. Customers expect speed, transparency, and a seamless experience from the first call to the final invoice. For small to midsize service businesses, mastering field service management is the key to not just surviving, but thriving. It's about transforming your operations from a reactive, chaotic scramble into a streamlined, data-driven machine. This means fewer missed appointments, happier technicians, and a healthier bottom line.

Moving beyond outdated methods like whiteboards and spreadsheets is no longer optional; it’s essential for growth and profitability. Efficiently managing your mobile workforce, inventory, and customer communications directly impacts customer retention and your ability to compete. Getting this right prevents lost revenue from missed calls, eliminates wasted trips for forgotten parts, and builds a reputation for reliability that earns repeat business and referrals.

This guide moves past generic advice to deliver nine actionable field service management best practices designed for immediate impact. We'll explore specific strategies you can implement to optimize every aspect of your service delivery, ensuring every technician is in the right place, at the right time, with the right tools to succeed. From leveraging AI to establishing meaningful KPIs, these tips will help you revolutionize your operations.

1. Implement Real-Time Scheduling and Dispatching

Static, pre-planned schedules are quickly becoming obsolete in modern field service. Implementing real-time scheduling and dispatching is one of the most impactful field service management best practices for boosting efficiency. This approach uses advanced software to dynamically assign jobs to technicians based on live data, including their current location, specific skill set, vehicle inventory, and real-time availability. This creates a flexible, adaptive system that can instantly respond to new service calls, cancellations, or delays.

For example, when an emergency call comes in, the system can automatically identify the closest, qualified technician who can be rerouted with minimal disruption to their existing schedule. This method moves beyond simply filling a calendar; it optimizes your entire daily operation for maximum productivity and customer satisfaction.

Why It Works

Real-time dispatching directly addresses the unpredictable nature of field service work. It minimizes technician travel time, reduces fuel costs, and increases the number of jobs a technician can complete in a day. Companies that adopt this practice often see significant improvements in key performance indicators.

Key Insight: The power of real-time dispatching lies in its ability to turn unforeseen events, like traffic jams or a job finishing early, into opportunities for optimization rather than sources of disruption.

For instance, Verizon leverages Oracle Field Service Cloud for dynamic scheduling of its 25,000+ technicians, while Honeywell Building Technologies cut its average response time by 30% using a similar approach.

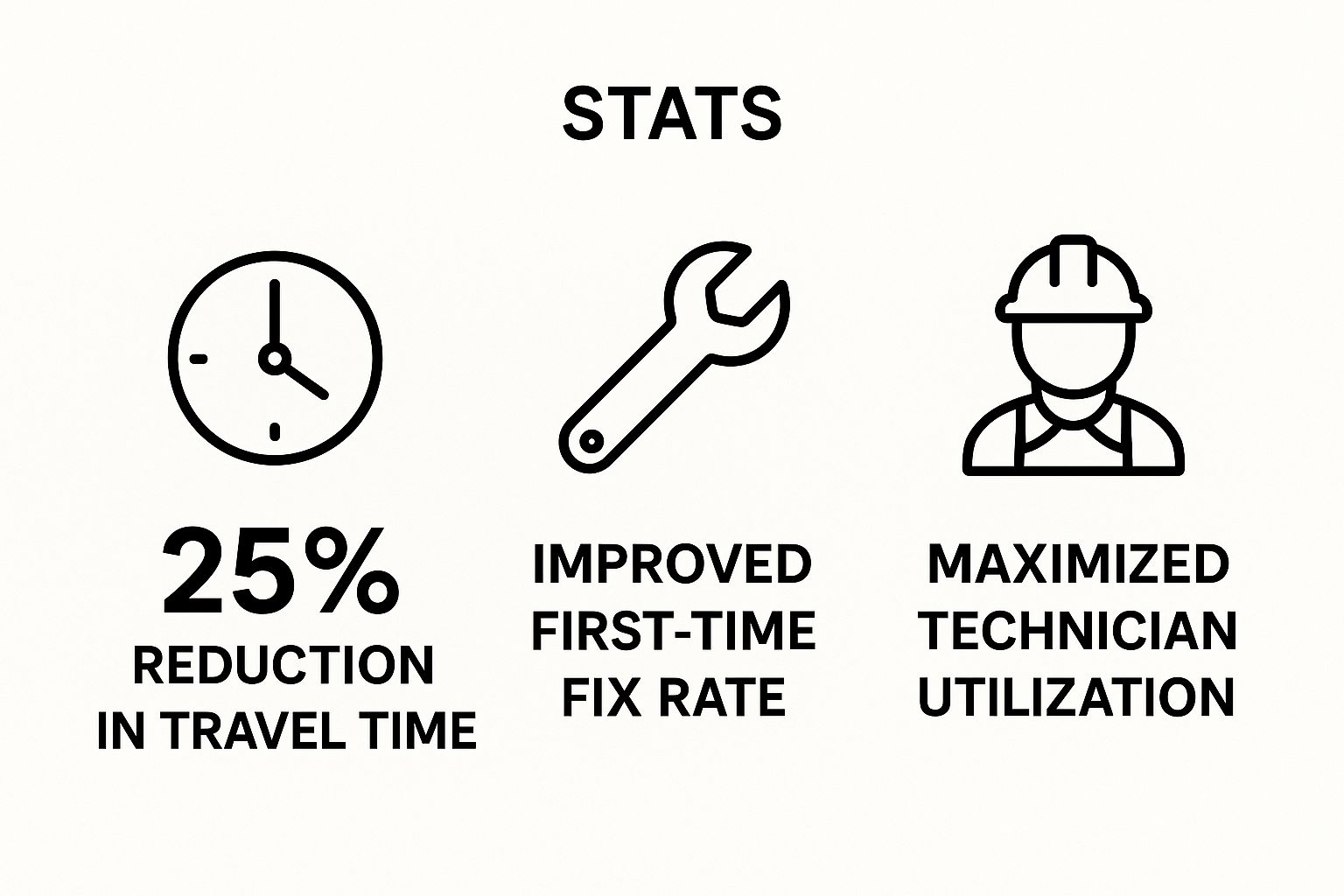

The following infographic highlights the concrete benefits businesses can achieve.

These statistics demonstrate how optimizing routes and assignments directly translates into higher revenue, better service quality, and more efficient use of your most valuable asset: your technicians.

How to Implement It

Successfully transitioning to a dynamic system requires a strategic approach.

- Start with a Pilot Program: Test the new software and processes in a specific territory or with a small group of technicians before a company-wide rollout. This helps identify and resolve issues on a smaller scale.

- Ensure Offline Capabilities: Your team will inevitably face areas with poor connectivity. Choose a mobile app that allows technicians to view and update job information offline, syncing automatically once a connection is restored.

- Provide Thorough Training: Dispatchers and technicians must be fully trained on the new system's capabilities to leverage its full potential. Focus training on how the software helps them make smarter, faster decisions.

2. Leverage Predictive Analytics for Preventive Maintenance

Shifting from a reactive to a proactive service model is a hallmark of advanced field service management best practices. Leveraging predictive analytics allows you to move beyond scheduled maintenance and address equipment issues before they cause failures. This approach uses historical data, IoT sensor readings, and machine learning algorithms to forecast when a specific component is likely to fail, enabling you to schedule service proactively.

This transforms your operation from an emergency repair service into a strategic partner that prevents downtime and extends equipment life. For example, instead of waiting for a commercial HVAC unit to break down during a heatwave, the system can flag a failing compressor weeks in advance, allowing for a planned, non-emergency replacement. This method maximizes asset uptime and drastically improves customer loyalty.

Why It Works

Predictive analytics minimizes costly, unplanned downtime and reduces the frequency of emergency call-outs, which are expensive and disruptive. By servicing equipment only when necessary, you optimize technician time and spare part inventory. This data-driven approach leads to more efficient operations, lower maintenance costs, and higher-value service contracts.

Key Insight: Predictive maintenance changes the service conversation from "What broke?" to "What can we do to ensure nothing breaks?" This positions your business as an indispensable asset-management partner, not just a repair service.

Major companies demonstrate the power of this approach. Otis Elevator uses its connected systems to predict maintenance needs, reducing callbacks by 50%. Similarly, Caterpillar's Asset Intelligence platform helps customers cut their maintenance costs by up to 20% by forecasting equipment issues.

How to Implement It

Integrating predictive analytics requires a focused, data-centric strategy.

- Start with Critical Assets: Begin your program by focusing on equipment where failure incurs the highest costs or poses the most significant disruption to your customers.

- Ensure Data Quality: The accuracy of your predictions depends entirely on the quality of your data. Ensure that information from sensors, maintenance logs, and work orders is consistent and clean.

- Build Confidence Gradually: Start by using predictive insights to supplement your existing maintenance schedules. As the system proves its accuracy, you can gradually transition to a fully predictive model and build trust with your technical team.

- Train Technicians on the 'Why': Technicians need to understand and trust the data. Provide training that explains how predictive insights are generated and how they help make their work more effective and less stressful.

3. Optimize Mobile Workforce Management

Effective mobile workforce management is a cornerstone of modern field service operations. This practice involves equipping field technicians with comprehensive mobile applications that serve as an all-in-one hub for their daily tasks. These apps provide instant access to work orders, detailed customer histories, technical manuals, and robust communication tools, ensuring technicians have every necessary resource at their fingertips. This approach keeps your team connected to the back office and fully informed while on-site.

For instance, a technician arriving at a job can use their mobile app to review the customer's complete service history, access schematics for the specific equipment, and document the repair with photos and notes. This eliminates trips back to the office for parts or information, directly improving first-time fix rates and overall efficiency.

Why It Works

Empowering technicians with mobile technology transforms them from isolated workers into connected, well-informed problem-solvers. This strategy dramatically reduces administrative burdens, minimizes paperwork errors, and accelerates the entire service-to-cash cycle. With real-time data capture, invoicing can be triggered the moment a job is completed.

Key Insight: Mobile workforce management isn't just about giving technicians a phone; it's about extending the full power of your back-office systems directly to the service location.

Major players have seen huge returns. British Gas, for example, improved its first-time fix rates from 85% to 95% after implementing a mobile workforce management solution. Similarly, Roto-Rooter saw a 25% increase in technician efficiency with its mobile app.

How to Implement It

A successful rollout of mobile tools requires careful planning and technician buy-in.

- Choose Appropriate Devices: Select ruggedized devices that can withstand field conditions like drops, dust, and moisture. Battery life is also a critical consideration for full-day shifts.

- Prioritize Offline Functionality: Service areas often have poor or no connectivity. Your chosen application must allow technicians to view and update job information offline, syncing data automatically once a connection is re-established.

- Implement Strong Security: Use mobile device management (MDM) policies to secure sensitive customer and company data on all devices, allowing you to remotely wipe a device if it is lost or stolen.

- Gather Technician Feedback: Involve your technicians in the selection and testing process. Regularly update the application based on their real-world feedback to ensure it remains a practical and valuable tool.

4. Implement Comprehensive Parts and Inventory Management

Effective parts management is the backbone of efficient field service, directly impacting first-time fix rates and technician productivity. Implementing a comprehensive parts and inventory management system is a crucial best practice that involves tracking components across warehouses, service vehicles, and technician stock. This practice ensures technicians have the right parts at the right time, preventing return visits and customer frustration.

Modern systems use technology to provide real-time visibility into your entire inventory. When a job is scheduled, the system can automatically check if the required parts are in the assigned technician's van. If not, it can orchestrate a transfer from another technician or a central warehouse, ensuring preparedness before the technician even heads to the site.

Why It Works

This practice transforms inventory from a reactive cost center into a proactive asset. By knowing exactly what you have and where, you can minimize costly stockouts, reduce carrying costs associated with overstocking, and significantly improve service delivery speed. This level of control is fundamental to achieving operational excellence.

Key Insight: Excellent inventory management isn't just about counting parts; it's about predicting demand and positioning assets strategically to eliminate delays and maximize the profitability of every service call.

For instance, Xerox maintains 99.5% parts availability using its global management system, while Carrier's HVAC division cut van stock by 30% while improving first-time fix rates. Similarly, Philips Healthcare reduced medical equipment part stockouts by 85% by optimizing its inventory.

How to Implement It

Adopting a robust inventory system requires a methodical approach for a smooth transition.

- Use ABC Analysis: Categorize your inventory. "A" items are high-value, critical parts that need tight control. "B" items are of moderate importance, and "C" items are low-cost, high-volume parts. This helps prioritize your management efforts where they matter most.

- Establish Cycle Counting: Instead of a disruptive annual inventory count, implement regular cycle counting. This involves counting small, specific subsets of inventory daily or weekly to maintain ongoing accuracy and quickly identify discrepancies.

- Optimize Van Stock: Regularly analyze parts usage data to determine the optimal stock for each service vehicle. This ensures technicians have the most frequently needed parts without carrying unnecessary inventory that increases fuel costs and risk of loss.

5. Enhance Customer Communication and Self-Service Options

Modern customers expect transparency and control over their service experiences. Enhancing customer communication and providing self-service options is a critical field service management best practice that meets this demand. This approach involves creating multiple touchpoints and digital channels where customers can schedule appointments, track technician arrival times, access service history, and even perform basic troubleshooting on their own.

For example, a customer portal can empower clients to book non-emergency services at their convenience, freeing up your phone lines for urgent calls. By giving customers direct access to information and simple actions, you reduce their uncertainty and improve their overall experience, all while lowering the administrative burden on your internal team.

Why It Works

This practice directly boosts customer satisfaction by providing the convenience and real-time updates that consumers are accustomed to from other industries, like e-commerce and package delivery. It reduces inbound calls for routine status checks, allowing your staff to focus on more complex issues. Self-service options also empower customers, building trust and loyalty.

Key Insight: Customer self-service is not about replacing human interaction; it's about making every necessary interaction more meaningful by automating the routine and predictable elements of the service journey.

Leading companies have seen significant results. For instance, Comcast's customer portal allows 60% of service appointments to be self-scheduled, while Home Depot's service tracking system improved its customer satisfaction scores by 25%. These examples show a direct link between customer empowerment and business success.

How to Implement It

Rolling out effective communication and self-service tools requires careful planning.

- Design Intuitive, Mobile-Friendly Interfaces: Your customer portal or app must be easy to navigate on any device. A clunky interface will deter use and create frustration.

- Offer Multiple Communication Channels: Cater to customer preferences by providing updates via SMS, email, and in-app notifications. Proactively alert them to any schedule changes or delays.

- Create Simple Troubleshooting Guides: Develop a library of clear, easy-to-follow guides with images or short videos to help customers resolve minor issues independently, like resetting a device or checking a pilot light.

- Gather and Act on Feedback: Regularly solicit feedback on your communication tools and self-service options to identify areas for improvement. You can learn more about customer service improvement strategies to refine your approach.

6. Establish Key Performance Indicators (KPIs) and Performance Management

You can't improve what you don't measure. Establishing comprehensive Key Performance Indicators (KPIs) and a structured performance management system is a foundational field service management best practice. This involves defining, tracking, and actively managing the metrics that directly impact operational success and customer satisfaction. It transforms raw data into actionable insights, creating accountability and highlighting specific areas for optimization.

By setting clear benchmarks, you empower both managers and technicians to understand what success looks like and how their individual actions contribute to the company's goals. For example, Johnson Controls uses real-time KPI dashboards to maintain a 95% on-time performance rate, while Schneider Electric’s focus on metrics increased its first-time fix rate from 75% to an impressive 90%.

Why It Works

A data-driven approach removes guesswork from management. Tracking KPIs like first-time fix rate, mean time to repair, and technician utilization provides an objective view of your operation's health. This allows you to identify top performers for recognition, pinpoint technicians who may need additional coaching, and make strategic decisions based on hard evidence rather than intuition.

Key Insight: Effective performance management isn't about policing your team; it's about providing the clarity and tools they need to succeed. When KPIs are transparent, they become a guide for continuous improvement, not just a tool for evaluation.

This practice, popularized by analytics platforms like Tableau and ServiceMax Analytics, gives leaders the visibility needed to steer the business effectively. Siemens, for instance, tracks 15 core KPIs across its global operations, which has contributed to a 20% improvement in overall efficiency.

How to Implement It

Rolling out a successful KPI program requires a focused, strategic effort.

- Focus on What Matters Most: Avoid "analysis paralysis" by tracking everything. Start with 5-8 core metrics that directly align with your primary business objectives, such as profitability, efficiency, and customer loyalty.

- Balance Efficiency and Quality: Ensure your KPIs provide a holistic view. Pair an efficiency metric like 'jobs per day' with a quality metric like 'first-time fix rate' or 'customer satisfaction score' to prevent technicians from rushing and sacrificing service quality.

- Use Data for Coaching: Regularly review performance data with your technicians in one-on-one sessions. Frame these conversations around coaching and development, providing specific, actionable feedback on how they can improve their results.

7. Implement Skills-Based Technician Management

Assigning the nearest technician is efficient, but sending the right technician is what prevents costly callbacks and ensures customer satisfaction. Skills-based technician management is a crucial field service management best practice that involves creating detailed profiles for each technician. These profiles catalog their specific competencies, certifications, and experience levels, allowing for more intelligent job assignments. This approach ensures that complex or specialized tasks are handled by the most qualified professional, leading to higher first-time fix rates.

For instance, when a call comes in for a specific model of a high-efficiency furnace, the system doesn't just look for the closest HVAC tech. It identifies the technician who is certified to work on that particular brand and has a proven track record of successful repairs. This strategic matching of skill to task is the foundation of a highly effective and reliable service operation.

Why It Works

This practice directly boosts service quality and operational efficiency. By sending a technician with the correct expertise, you drastically reduce the chance of a second visit, saving on labor and travel costs while increasing customer trust. It also empowers technicians by assigning them jobs they are confident and competent in completing.

Key Insight: Skills-based management transforms your workforce from a general pool of labor into a strategic asset. It allows you to precisely deploy expertise where it's needed most, turning potential service failures into successes.

For example, Philips uses competency mapping for its technicians to achieve a 95% first-time fix rate on complex medical equipment. Similarly, Otis Elevator implemented a technician skills matrix that helped reduce callbacks by an impressive 40%.

This targeted approach is a cornerstone of effective business process improvement. You can discover more about business process improvement methods on marlie.ai to see how this fits into a larger optimization strategy.

How to Implement It

Putting a skills-based system into action requires a clear, methodical approach.

- Create Detailed Skill Matrices: Develop a comprehensive matrix that lists all your service offerings and maps them to specific skills, certifications, and proficiency levels (e.g., Novice, Proficient, Expert).

- Conduct Regular Skills Assessments: Don't let your skills data become outdated. Implement a process for regular assessments and encourage technicians to log new certifications or training completions in real-time.

- Balance Specialization with Cross-Training: While specialists are invaluable, over-specialization can create bottlenecks. Use your skills data to identify training gaps and implement cross-training programs to build a more flexible and resilient team.

8. Leverage Artificial Intelligence and Automation

Integrating artificial intelligence (AI) and automation is a transformative step in optimizing field service operations. This practice involves using machine learning, natural language processing, and robotic process automation to intelligently handle tasks that traditionally require human intervention. This includes automated scheduling, AI-powered diagnostics, customer service chatbots, and predictive analytics to forecast maintenance needs or parts demand.

For example, when a technician is on-site, AI can help diagnose complex equipment issues with remarkable accuracy, turning a novice into an expert. Similarly, AI-driven scheduling can optimize routes and assignments far beyond human capability, considering hundreds of variables simultaneously. This isn't just about efficiency; it's about embedding intelligence into every facet of your service delivery.

Why It Works

AI and automation address core field service challenges like diagnostic accuracy, operational efficiency, and customer communication. By automating routine tasks and providing data-driven insights, these technologies free up your team to focus on high-value work. This is a critical field service management best practice for companies aiming to scale operations without a proportional increase in overhead.

Key Insight: The true power of AI in field service is its ability to move from a reactive model (fixing what's broken) to a predictive one (fixing what's about to break), fundamentally changing the value you provide to customers.

Companies like Bosch are already seeing massive benefits, using AI to optimize over 10,000 daily service appointments. Meanwhile, IBM Watson helps Harley-Davidson technicians diagnose motorcycle issues with up to 85% accuracy, drastically reducing repair times and improving first-time fix rates. Learn more about the benefits of business process automation on marlie.ai.

How to Implement It

Adopting AI requires a measured and strategic approach to ensure successful integration.

- Start with Specific Use Cases: Don't try to automate everything at once. Begin with a pilot program targeting a high-impact area, such as automated appointment scheduling or an AI chatbot for initial customer inquiries.

- Prioritize Data Quality: AI systems are only as good as the data they are trained on. Ensure you have strong data governance policies to maintain clean, accurate, and consistent information across your systems.

- Maintain Human Oversight: Use AI as a tool to augment, not replace, your team. Critical decisions, especially those involving complex customer issues or safety, should always have a human in the loop for final approval.

9. Develop Continuous Training and Knowledge Management

In a rapidly evolving industry, the knowledge your technicians had last year may not be sufficient for the technology they face tomorrow. Developing a system for continuous training and knowledge management is a critical field service management best practice. It involves creating a structured approach to keep your team updated on new products, complex repair procedures, and evolving safety standards through a centralized, easily accessible repository of information.

This goes beyond a one-time onboarding session. It's about building a living library of resources, from video tutorials and digital manuals to peer-to-peer forums. For example, when a technician encounters a new smart appliance model in the field, they can instantly access a mobile-friendly knowledge base for schematics and repair guides, resolving issues faster without needing to call a senior technician or the main office.

Why It Works

A robust knowledge management system empowers technicians to be more autonomous, confident, and efficient. It reduces first-time fix failures, minimizes costly repeat visits, and ensures a consistent level of service quality across your entire team. Companies that invest in continuous learning see significant improvements in technician performance and customer satisfaction.

Key Insight: The goal of knowledge management isn't just to store information; it's to deliver the right knowledge to the right technician at the exact moment of need, turning a potential roadblock into a successful service call.

For instance, Caterpillar's virtual reality program cut equipment training time by 50%, while Maytag's digital knowledge base allows technicians to find repair procedures in under 30 seconds.

How to Implement It

Building an effective learning ecosystem requires more than just buying software.

- Start with Microlearning Modules: Technicians have busy, unpredictable schedules. Deliver training in short, digestible formats like 3-5 minute videos or quick reference guides that can be accessed on a mobile device between jobs.

- Create a Peer Mentoring Program: Pair experienced technicians with newer team members. This fosters a collaborative culture and allows practical, real-world knowledge to be passed down efficiently. It also gives your senior technicians a valuable leadership role.

- Gamify Learning to Boost Engagement: Introduce points, badges, or leaderboards for completing training modules or contributing to the knowledge base. This friendly competition can significantly increase participation and knowledge retention.

Field Service Management Best Practices Comparison

| Practice | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Implement Real-Time Scheduling and Dispatching | High – complex integration and technology | Significant upfront tech investment, reliable internet | Reduces travel time 25%, improves first-time fix, maximizes utilization | Dynamic, large-scale field service operations | Responsive scheduling, emergency call agility |

| Leverage Predictive Analytics for Preventive Maintenance | High – requires data infrastructure & expertise | Substantial data collection, skilled data scientists | Reduces downtime 30-50%, lowers costs, extends equipment life | Critical, high-failure-cost equipment | Proactive maintenance, fewer unexpected failures |

| Optimize Mobile Workforce Management | Moderate – app deployment and device management | Mobile devices, training, device management | Cuts admin time, improves data accuracy, enhances communication | Field technicians needing mobility & connectivity | Digital forms, real-time updates, offline capability |

| Implement Comprehensive Parts and Inventory Management | High – multi-location tracking complexity | Systems for real-time tracking & forecasting | Reduces stockouts, lowers carrying costs, improves first-time fix rates | Operations with large parts inventory | Optimized inventory, reduced travel for parts pickup |

| Enhance Customer Communication and Self-Service Options | Moderate – portal/communication setup | Development of portals, automated notifications | Lowers call volume 30-40%, improves satisfaction & transparency | Customer-centric service models | 24/7 scheduling, customer empowerment |

| Establish Key Performance Indicators (KPIs) and Performance Management | Moderate – dashboard & data maintenance | Data collection tools, analytics platforms | Improves visibility & accountability, drives continuous improvement | Operations focusing on performance metrics | Data-driven decisions, targeted coaching |

| Implement Skills-Based Technician Management | Moderate to High – data tracking & scheduling | Skill tracking tools, ongoing assessments | Increases first-time fix 15-25%, boosts job satisfaction | Services requiring specialist assignments | Better job matching, training efficiency |

| Leverage Artificial Intelligence and Automation | High – advanced AI integration | High tech expertise, data quality controls | Cuts costs 20-30%, improves scheduling & diagnostics | Operations seeking automation and efficiency | AI diagnostics, 24/7 customer support |

| Develop Continuous Training and Knowledge Management | Moderate – content creation & LMS maintenance | Learning platforms, content developers | Reduces onboarding time 40%, improves fix rates & retention | Organizations focused on skill development | Rapid knowledge transfer, increased technician confidence |

Putting Your Field Service Plan into Action

Transitioning from knowing about field service management best practices to actively implementing them is the single most important step you can take for your business's future. The journey we've outlined, from real-time dispatching to AI-powered automation, isn't about achieving overnight perfection. Instead, it’s about a commitment to continuous, strategic improvement that builds momentum with each successful change.

For a small to midsize service business, where every single phone call represents a potential job, the sheer volume of these "best practices" can seem overwhelming. You might be a solo tow operator juggling a lockout call while winching a vehicle, or an HVAC owner trying to schedule an emergency burst-pipe job after hours. In these scenarios, the foundational challenge isn't just optimizing operations; it's capturing every opportunity in the first place. You can't optimize a job you never booked because the call went to voicemail.

Your Roadmap to Implementation

The key is to approach this as an iterative process. Start by identifying the single biggest bottleneck holding your business back right now.

- If you're losing jobs after hours: Your first priority is capturing every lead, 24/7. This makes enhancing customer communication and leveraging automation your most critical starting point.

- If technicians are wasting time driving: Focus on real-time scheduling and route optimization to immediately cut fuel costs and increase job capacity.

- If first-time fix rates are low: Your efforts should center on comprehensive inventory management and continuous skills training to ensure techs arrive prepared.

By adopting this mindset, you can see these principles not as a daunting checklist, but as a flexible toolkit. Pick the tool that solves your most pressing problem today, master it, and then move on to the next.

Key Takeaway: True optimization begins with a solid foundation. You must first ensure your business can reliably capture and qualify every incoming service request before you can effectively manage and execute it.

Mastering these field service management best practices ultimately translates into a more resilient, profitable, and scalable business. It means happier customers who receive faster service, more empowered technicians who have the tools to succeed, and less stress for you as a business owner. It is the bridge between constantly reacting to emergencies and proactively steering your company toward sustainable growth. Each step you take, no matter how small, compounds over time, creating a powerful competitive advantage that sets you apart in a crowded market.

Ready to build a rock-solid foundation for your service operations? Marlie Ai handles your most critical first step by answering every call, booking jobs, and collecting customer details 24/7, so you never miss a lead. Stop losing revenue to voicemail and start focusing on growth by visiting Marlie Ai to see how our AI-powered voice agent can transform your front line.