In today's competitive market, efficiency isn't just an advantage; it's a requirement for survival and growth. For service-based businesses, from a solo locksmith juggling calls on the road to a multi-truck HVAC company trying to manage seasonal spikes, the gap between a booked job and a lost lead often comes down to one thing: process. How you answer the phone, dispatch a technician, and follow up with a customer are all processes that can either fuel your growth or drain your resources. This is where business process improvement methods become critical tools, not just corporate buzzwords.

These structured frameworks are designed to help you systematically identify and eliminate the hidden friction in your daily operations. They target the root causes of inefficiency, whether it's wasted time, costly errors, or inconsistent customer experiences. For an owner-operator, applying these principles means more time to focus on high-value work instead of administrative headaches. For a growing service company, it means building a scalable operation that delivers consistent quality without adding unnecessary overhead.

This guide moves beyond theory to provide a practical roadmap. We will explore nine powerful business process improvement methods, breaking each one down into actionable steps tailored for service-based entrepreneurs. You will learn how to adapt proven strategies like Lean, Six Sigma, and Agile to solve real-world problems, such as streamlining your urgent call handling, optimizing technician dispatching, and ensuring every customer interaction reinforces your reputation. Forget abstract concepts; this is about tangible results that lead to more completed jobs, higher profits, and a stronger, more resilient business.

1. Lean Manufacturing

While its name suggests a focus on physical production lines, Lean Manufacturing is one of the most foundational business process improvement methods adaptable to any industry, including service-based businesses. At its core, Lean is a systematic philosophy for maximizing customer value while minimizing waste. It’s not about cutting corners; it’s about relentlessly eliminating any step, task, or resource that doesn't directly contribute to what the customer is willing to pay for.

For a service business, "waste" isn't defective parts but wasted time, redundant paperwork, or unnecessary trips. Think of a plumber having to return to the shop for a forgotten tool (waste of motion) or a dispatcher entering customer data into three different systems (waste of over-processing). By applying Lean principles, you systematically identify and remove these inefficiencies, resulting in faster service, lower operating costs, and a more streamlined customer experience.

When and Why to Use Lean

Lean is ideal when your primary goals are to increase efficiency, reduce operational costs, and improve the quality and speed of your service delivery. It is particularly effective for businesses that have repetitive processes, such as client onboarding, job dispatching, or invoicing. If your team complains about "the way we've always done it" being slow or clunky, or if you notice significant delays between a customer call and service completion, Lean provides a structured framework to diagnose and solve the root causes.

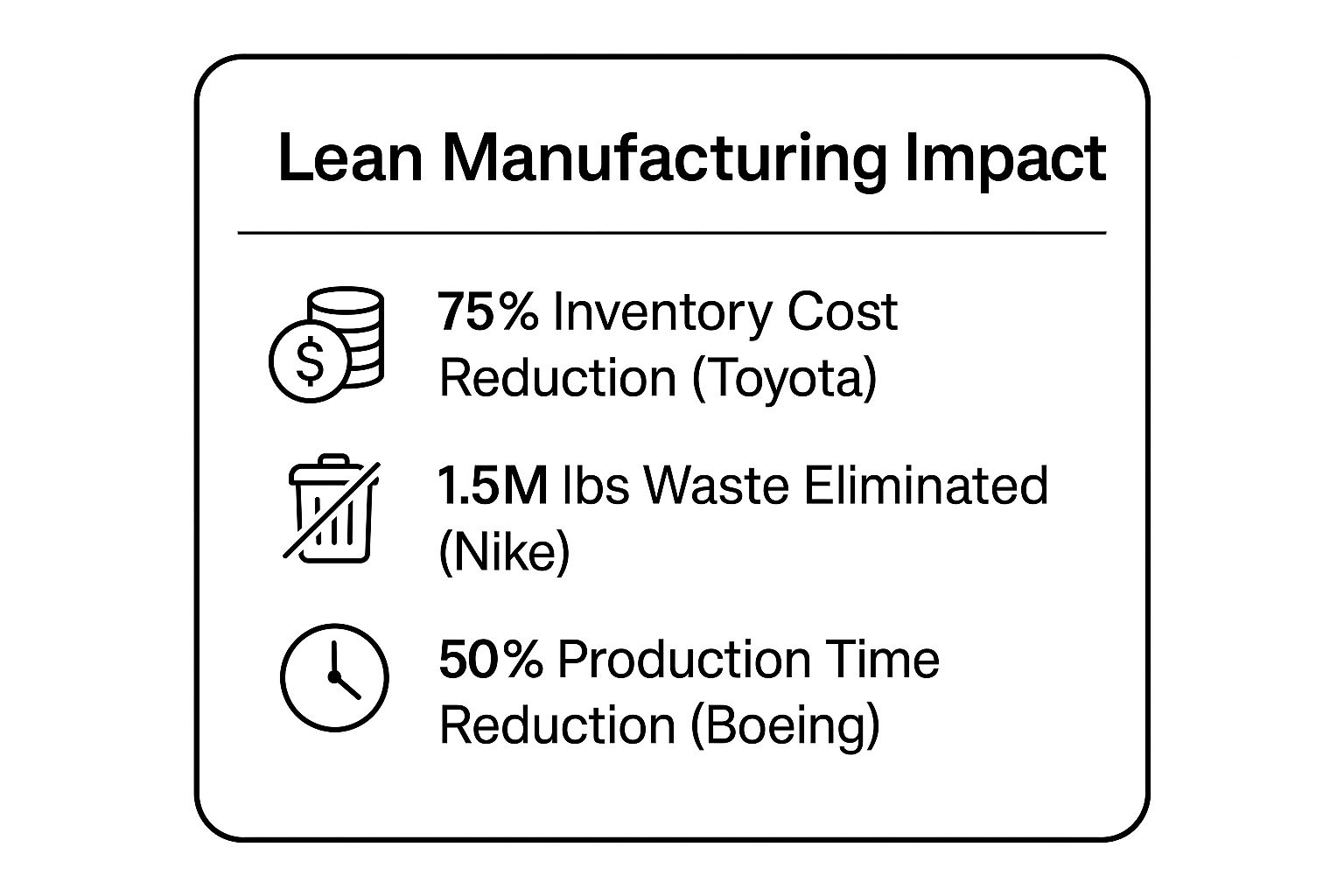

The real-world impact of adopting a Lean mindset is significant, leading to dramatic improvements in cost, waste, and speed.

These figures from manufacturing giants demonstrate Lean's power to transform core operational metrics, a principle that directly translates to service industry success.

Actionable Tips for Service Businesses

- Map Your "Value Stream": Don't be intimidated by the term. Simply grab a whiteboard and chart every single step from a customer's initial call to the final payment. Identify which steps add direct value (e.g., diagnosing the problem, fixing the appliance) and which are "waste" (e.g., waiting for approval, re-entering information). This map is your treasure map for finding improvement opportunities.

- Implement 5S in Your Workspace and Vehicles: 5S (Sort, Set in Order, Shine, Standardize, Sustain) is a perfect starting point. For a tow truck operator, this means organizing tools and equipment in the truck so everything has a designated place. This simple discipline prevents wasted time searching for a specific strap or tool during a critical roadside recovery.

- Engage Your Technicians: Your frontline employees know where the real problems are. Hold brief weekly meetings to ask, "What slowed you down last week?" or "What part of our process is frustrating?" Empower them to suggest and implement small changes. This bottom-up approach is a hallmark of Lean and ensures practical, effective solutions.

2. Six Sigma

Where Lean focuses on speed and waste elimination, Six Sigma is a data-driven business process improvement method laser-focused on quality and consistency. Its goal is to reduce process variation to an absolute minimum, thereby eliminating defects and errors. The "Six Sigma" name refers to a statistical goal of having a process that is so consistent that it produces no more than 3.4 defects per million opportunities.

For a service business like a locksmith or an HVAC company, a "defect" might not be a faulty product but an incorrect diagnosis, a missed appointment, or an inaccurate invoice. Each of these errors creates customer frustration and rework, which hurts profitability. By using Six Sigma's statistical tools, you can pinpoint the root causes of these inconsistencies and implement solutions that make your service delivery nearly flawless. This disciplined approach was famously championed by giants like Motorola and General Electric, who saved billions by improving process quality.

When and Why to Use Six Sigma

Six Sigma is the right choice when your primary challenge is inconsistency, customer complaints, or costly errors. If you find your technicians deliver varying levels of service quality, or if your dispatch process frequently sends the wrong information, Six Sigma provides the framework to standardize and perfect these operations. It is particularly powerful for processes where precision is critical, such as quoting complex jobs, ordering specific parts, or managing compliance paperwork.

By focusing on reducing variation, Six Sigma directly impacts customer satisfaction and your bottom line. Fewer errors mean fewer repeat visits, less wasted material, and a stronger reputation for reliability.

Actionable Tips for Service Businesses

- Start with a High-Impact Project: Don't try to boil the ocean. Identify one recurring, frustrating problem, like frequent parts-ordering mistakes that delay repairs. Use the Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) framework to tackle just that one issue. A quick, measurable win will build momentum and demonstrate the method's value.

- Focus on Key Metrics: You don't need to be a statistician to start. Begin by measuring simple but critical metrics. For an emergency towing company, this could be "dispatch accuracy" (the percentage of calls where the location and vehicle details are 100% correct) or "first-time fix rate" for a mobile mechanic. Track this data consistently to find patterns.

- Empower a "Champion": Six Sigma requires dedicated focus. Designate one person, perhaps an operations manager or a senior technician, to "own" the improvement project. Providing them with basic training (many online certifications are available) and the authority to implement changes is crucial. This ensures the initiative has strong leadership and doesn't get pushed aside by daily urgencies.

3. Business Process Reengineering (BPR)

Unlike methods that focus on small, continuous improvements, Business Process Reengineering (BPR) is a radical approach among business process improvement methods, calling for a complete and fundamental redesign of core processes. Popularized by pioneers like Michael Hammer, BPR isn't about tweaking the existing system; it's about starting from a blank slate to achieve dramatic gains in performance, cost, quality, and speed. It asks the question, "If we were starting this company today, knowing what we know now, how would we build this process?"

For a service business, this means fundamentally challenging how work gets done. Instead of just speeding up a multi-step dispatch process, BPR might question why dispatch, invoicing, and customer follow-up are separate functions at all. As demonstrated by Ford, which reduced its accounts payable staff by 75% by reengineering its procurement process, the goal is transformative, not incremental. It's about rethinking the work itself to eliminate non-value-added tasks entirely.

When and Why to Use BPR

BPR is the right choice when incremental improvements are no longer sufficient to meet business goals or competitive pressures. It is best suited for processes that are critically broken, outdated, or creating major customer dissatisfaction. If your company is facing significant changes, such as new market entry, disruptive technology, or a major shift in customer expectations, BPR provides a framework for a bold, top-down overhaul.

This method is high-risk but high-reward, aiming for quantum leaps in performance rather than small steps. It's for when you need to revolutionize, not just refine.

Actionable Tips for Service Businesses

- Start with Customer Impact: Identify the core process that most directly affects your customers' experience. For an emergency towing company, this might be the entire cycle from the initial frantic call to the vehicle's safe delivery. Reengineering this single, critical process will deliver the most significant and visible results.

- Use Technology as an Enabler: View technology not just as a tool for automation but as a way to enable entirely new ways of working. For example, instead of just automating an old paper form, use a mobile app that allows technicians to capture job data, process payments, and get customer sign-off in a single step, eliminating backend office work. This is a core benefit of business process automation.

- Involve Employees in the Redesign: While BPR is often driven from the top, the employees who perform the work daily possess invaluable insights. Create cross-functional teams with technicians, dispatchers, and administrative staff to map out and reinvent the process. This ensures the new design is practical and builds buy-in from the start.

4. Total Quality Management (TQM)

Total Quality Management (TQM) is a comprehensive management philosophy where every department, process, and employee is dedicated to continuous improvement. Unlike methods that focus on specific workflows, TQM embeds a culture of quality into the very fabric of the organization. It’s one of the most holistic business process improvement methods, asserting that long-term success comes from unwavering customer satisfaction and active employee participation.

For a service business, this means quality isn't just about the final repair or installation. It's about the quality of the initial phone call, the accuracy of the scheduling, the professionalism of the technician, and the clarity of the invoice. TQM champions like Toyota and Ritz-Carlton built their reputations by making quality everyone's responsibility, from the CEO to the frontline worker. The core principle is preventing defects and errors before they happen, rather than just fixing them afterward.

When and Why to Use TQM

TQM is the right approach when you want to build a long-term reputation for excellence and reliability. It's less of a quick fix and more of a cultural transformation. Consider TQM if you're experiencing inconsistent service quality across different technicians or locations, or if customer complaints point to systemic issues rather than one-off mistakes. If your goal is to be the "gold standard" in your market, known for unparalleled customer service and operational integrity, TQM provides the framework.

Pioneered by figures like W. Edwards Deming, this philosophy shifts the focus from short-term profits to long-term quality, which ultimately drives customer loyalty and sustainable growth.

Actionable Tips for Service Businesses

- Secure Leadership Commitment: TQM starts at the top. As the business owner, you must visibly champion the commitment to quality. Define what "quality" means for your business-is it a 30-minute response time, a zero-callback guarantee, or a 99% customer satisfaction score? Communicate this vision relentlessly to your team.

- Focus on Customer Requirements: Systematically gather customer feedback through surveys, follow-up calls, or online reviews. Don't just collect it; analyze it to understand what customers truly value. A customer might care more about the technician arriving within the promised window than the repair taking 10 minutes less. Use this data to define your quality standards.

- Empower and Train Employees: Provide your team with the training and tools needed to achieve quality standards. This could include technical skills, customer service training, or problem-solving techniques. Create a "no-blame" environment where employees feel safe to report issues or suggest improvements, turning them into active participants in the quality process.

5. Agile Methodology

Though it originated in the fast-paced world of software development, the Agile Methodology has become one of the most powerful business process improvement methods for any company facing unpredictable challenges and changing customer needs. Agile is an iterative approach that prioritizes flexibility, collaboration, and speed. Instead of creating a rigid, long-term plan, Agile breaks large projects into small, manageable cycles called "sprints," allowing teams to adapt and improve continuously.

For a service business, this means moving away from a "plan it all at once" mindset to one of rapid response. Imagine an HVAC company launching a new maintenance plan. The old way involves months of planning. The Agile way involves launching a basic version to a small customer group, gathering feedback, and then refining the offering in short, focused bursts. This approach ensures the final service perfectly matches what customers actually want, not what you think they want.

When and Why to Use Agile

Agile is the ideal framework when you're working on complex projects with unclear requirements or when you operate in a market where customer expectations can shift quickly. It’s perfect for launching new services, redesigning your customer intake process, or implementing new technology like a dispatching system. If your team struggles with projects that drag on for months and deliver disappointing results, Agile’s focus on short cycles and continuous feedback can be transformative.

The methodology's strength lies in its ability to reduce risk and deliver value faster. By building and testing in small increments, you can catch problems early and pivot without derailing the entire project, ensuring your resources are always focused on the most impactful work.

Actionable Tips for Service Businesses

- Start with Small, Cross-Functional Teams: Create a small team to tackle a specific improvement, like reducing appointment no-shows. This team should include a technician, a dispatcher, and maybe even the owner. This mix of perspectives ensures all angles of the problem are considered, leading to more robust solutions.

- Focus on Delivering Working Solutions Quickly: Don't try to perfect a new process on paper. Instead, aim to implement a "good enough" version within a two-week sprint. For example, you could test a new automated appointment reminder text for just one technician's schedule. This lets you see real-world results immediately.

- Embrace Daily Stand-ups: Hold a 15-minute daily meeting where each team member answers three questions: What did I do yesterday? What will I do today? What is blocking my progress? This simple ritual keeps everyone aligned, promotes accountability, and quickly surfaces any roadblocks that need to be cleared.

6. Kaizen

Unlike project-based overhauls that seek dramatic, disruptive change, Kaizen is a Japanese philosophy centered on continuous, incremental improvement. It is one of the most powerful business process improvement methods because it fosters a company-wide culture where every single employee, from the owner to the newest technician, is empowered to identify and implement small, ongoing enhancements. The core idea is that many small changes over time lead to massive, sustained positive results.

For a service business, this isn't about a single, expensive software rollout. Instead, it's about a technician suggesting a better way to organize their van, a dispatcher creating a small checklist to reduce errors, or a manager holding a brief weekly meeting to discuss what went right and what could be one percent better. These small, consistent efforts compound, leading to significant gains in efficiency, quality, and morale without the disruption of a large-scale project.

When and Why to Use Kaizen

Kaizen is the ideal approach when you want to build a long-term culture of excellence rather than just complete a one-time project. It is particularly effective for businesses that want to empower their employees and tap into their frontline knowledge. If you're looking to make steady, sustainable progress in areas like customer satisfaction, operational efficiency, and employee engagement, Kaizen provides the framework. It shifts the mindset from "this is a problem for management" to "how can we all make this better today?"

By focusing on small, low-cost, and low-risk improvements, Kaizen reduces resistance to change and builds momentum. It’s a perfect fit for service businesses like locksmiths or HVAC contractors where field staff are best positioned to identify day-to-day inefficiencies. This gradual approach is key to improving your customer service strategies in a way that truly lasts.

Actionable Tips for Service Businesses

- Start with "Gemba" Walks: "Gemba" is the Japanese term for "the actual place" where work happens. As a business owner, walk the shop floor, ride along with a technician, or listen in on customer calls. Observe the real process, ask questions, and listen to the team's frustrations and ideas without judgment.

- Implement an "Idea Board": Place a simple whiteboard in a common area where any employee can write down a small problem or an idea for improvement. Review these ideas in a weekly huddle, and empower the team to test the simple ones immediately. This makes improvement visible and collaborative.

- Celebrate Small Wins: When a technician’s suggestion to pre-assemble a common repair kit saves five minutes per job, celebrate it. Acknowledge the person and the impact in a team meeting. This positive reinforcement is the fuel for a Kaizen culture and encourages everyone to keep looking for the next small improvement.

7. Value Stream Mapping

While many methods focus on individual tasks, Value Stream Mapping (VSM) provides a bird's-eye view of your entire operation from start to finish. It is a powerful visualization tool used to analyze the complete flow of information and steps required to deliver a service to a customer. By physically drawing out this flow, you can clearly see not just the tasks themselves, but the waiting periods and handoffs in between, which are often the biggest sources of inefficiency.

For a service business like an HVAC company, the value stream starts when a customer's AC unit fails and ends when their system is running again and the invoice is paid. VSM helps you see the entire journey, identifying waste like a technician waiting for a part, a dispatcher re-entering job details into a separate billing system, or a customer waiting for a callback. It makes the invisible flow of work visible, allowing you to pinpoint and eliminate bottlenecks.

When and Why to Use Value Stream Mapping

Value Stream Mapping is the perfect tool when you feel your process is inefficient but can't pinpoint the exact cause, or when improvements in one area don't seem to impact the overall delivery time. It’s ideal for visualizing complex processes with multiple handoffs, such as emergency dispatch, multi-stage repair jobs, or client onboarding and billing. If you need to understand the big picture before diving into smaller fixes, VSM provides the necessary context.

By analyzing the "current state" map, teams can design a leaner, more efficient "future state" map. Companies like Amazon have famously used these principles to streamline their fulfillment processes, reducing the time from click to delivery. This comprehensive approach is a cornerstone of effective business process improvement methods.

Actionable Tips for Service Businesses

- Start with a High-Impact Process: Don't try to map your entire business at once. Pick one critical, high-volume service, like emergency lockout calls for a locksmith or burst-pipe repairs for a plumber. Mapping this process first will yield the most significant returns.

- Involve the Whole Team: When you create your map, include everyone involved in the process: the person who answers the phone, the dispatcher, the technician, and the person who handles billing. Each person provides a unique and essential perspective on where delays and frustrations occur.

- Use Real Data, Not Guesses: Walk the process yourself. Time how long each step actually takes and, more importantly, how long the waiting periods are between steps. Use a stopwatch and sticky notes. The goal is to capture what is truly happening, not what you think should be happening.

- Focus on Customer Value: As you map, continually ask, "Does this step add value from the customer's perspective?" A customer values a quick diagnosis and a completed repair; they don't value the time your technician spends searching for a part or waiting for a work order to be approved. This question helps you ruthlessly identify and target waste for elimination.

8. Theory of Constraints (TOC)

The Theory of Constraints (TOC) is one of the most powerful business process improvement methods because it focuses on the single biggest limiting factor in any process. Developed by Eliyahu M. Goldratt, TOC operates on a simple premise: a chain is only as strong as its weakest link. In your business, that "weakest link" is the constraint or bottleneck that dictates the maximum output of your entire system.

For a service business, a constraint might not be a machine but a person or a process. It could be your most experienced technician who is the only one qualified for complex jobs, a single dispatcher handling all incoming calls during peak hours, or a slow approval process for ordering specialty parts. TOC provides a laser-focused methodology to identify this bottleneck and subordinate all other operations to improve its performance, thereby lifting the performance of the entire business.

When and Why to Use TOC

TOC is the ideal method when you feel like you're working harder but not getting more done, or when one part of your workflow is consistently holding up everything else. If your technicians are often waiting for parts, your dispatch queue is constantly backed up, or your invoicing process delays cash flow, TOC offers a systematic way to find and fix that single point of failure. It's particularly effective for service businesses where time is a critical factor, like emergency towing or HVAC repair.

By addressing the primary bottleneck, businesses can achieve dramatic improvements in throughput and profitability. For more insights on how streamlining operations can directly impact your bottom line, you can learn more about increasing business revenue here.

Actionable Tips for Service Businesses

- Identify Your True Constraint: Don't just guess. Analyze your workflow from start to finish. Where do jobs pile up? Is it your phone lines during a storm, the availability of a specific piece of diagnostic equipment, or the time it takes to get customer payment information? That pile-up point is your constraint.

- Exploit the Constraint: Once identified, your top priority is to ensure the constraint is always operating at maximum capacity on value-added work. If your best locksmith is the constraint, make sure their schedule is filled only with jobs only they can do, and offload administrative tasks or simpler jobs to others.

- Subordinate Everything Else: Align every other part of your process to support the constraint. This means non-constraint resources should not work at their full capacity if it means overwhelming the bottleneck. If your dispatcher is the constraint, your marketing should be paced to not generate more calls than they can effectively handle.

- Use Buffer Management: Protect your constraint from disruptions. For a towing company whose heavy-duty wrecker is the bottleneck, a "buffer" could mean having preventative maintenance scheduled during non-peak hours and ensuring all necessary straps and tools are always ready to go. This buffer ensures the constraint never sits idle waiting for work.

9. Statistical Process Control (SPC)

Statistical Process Control (SPC) is a data-driven business process improvement method that uses statistical tools to monitor, control, and improve a process. Rather than waiting for a problem to occur, SPC allows a business to see process variations in real-time, helping to predict and prevent issues before they result in poor service or wasted resources. It’s about moving from a reactive "fix-it" mentality to a proactive, data-informed state of control.

For a service business, this means tracking key performance metrics to ensure consistency. Think of a towing company monitoring its average response time or a locksmith tracking the percentage of first-time successful lock openings. By using control charts, you can visually distinguish between "common cause variation" (the normal, acceptable fluctuations in a process) and "special cause variation" (an unexpected event that needs immediate investigation). This helps you avoid overcorrecting for normal fluctuations while quickly addressing real problems.

When and Why to Use SPC

SPC is ideal when you need to ensure the consistency and predictability of critical processes that directly impact customer satisfaction and operational costs. It is particularly powerful for service businesses with high-volume, repetitive tasks, such as call center handling, dispatching, or even repair diagnostics. If you experience inconsistent service quality or if customer satisfaction scores fluctuate wildly without a clear reason, SPC provides the tools to stabilize your operations.

Pioneered by figures like Walter Shewhart at Bell Labs, SPC has a proven track record of reducing defects and improving quality, principles that are just as applicable to service delivery as they are to manufacturing.

Actionable Tips for Service Businesses

- Start with Measurable Outputs: Identify a critical process with a clear, measurable outcome. This could be the time it takes to complete a service call, the number of follow-up visits required, or the daily call abandonment rate. You need tangible data to build your control charts.

- Establish Control Charts: Use simple software or even a spreadsheet to plot your process data over time. Calculate the average and then establish upper and lower control limits (typically three standard deviations from the average). This chart becomes your dashboard for process stability.

- Create Clear Response Plans: Define exactly what your team should do when a data point falls outside the control limits. This "out-of-control" signal requires investigation. Was there a new dispatcher on duty? A system outage? A problem with a specific technician's equipment? This turns data into actionable intelligence.

- Train Your Team on the Basics: Your employees don't need to be statisticians, but they should understand what the control chart means. Teach them to recognize a stable process versus an out-of-control one and empower them to flag issues when they see them.

Business Process Improvement Methods Comparison

| Methodology | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Lean Manufacturing | Moderate to High – requires cultural change and training 🔄🔄 | Moderate – training and continuous management ⚡⚡ | Waste reduction, cost savings, faster lead times 📊📊 | Manufacturing environments seeking efficiency and waste elimination | Cost reduction, quality improvement, employee engagement ⭐⭐ |

| Six Sigma | High – requires specialized training and data analysis 🔄🔄🔄 | High – certification and statistical tools ⚡⚡ | Defect reduction, process variation control 📊📊📊 | Processes needing precision and defect minimization | Defect reduction, cost savings, analytical rigor ⭐⭐⭐ |

| Business Process Reengineering (BPR) | Very High – radical redesign and change management 🔄🔄🔄🔄 | High – resource intensive and time-consuming ⚡⚡ | Dramatic performance improvement, cost reduction 📊📊 | Organizations needing fundamental process overhaul | Dramatic improvements, technology leverage, customer focus ⭐⭐ |

| Total Quality Management (TQM) | High – cultural transformation and long-term commitment 🔄🔄🔄 | Moderate to High – ongoing training and involvement ⚡⚡ | Improved quality, customer satisfaction, long-term gains 📊📊 | Organizations focused on quality and continuous improvement | Organization-wide quality focus, employee empowerment ⭐⭐ |

| Agile Methodology | Moderate – requires team training and adaptability 🔄🔄 | Moderate – skilled teams and coaching ⚡⚡⚡ | Faster delivery, adaptability, customer collaboration 📊📊 | Projects needing flexibility and rapid iterations | Speed to market, adaptability, team communication ⭐⭐⭐ |

| Kaizen | Low to Moderate – incremental improvements and employee involvement 🔄 | Low – minimal cost, continuous engagement ⚡⚡ | Continuous, incremental improvements and waste reduction 📊📊 | Cultures focusing on ongoing small improvements | Low cost, employee engagement, sustainable culture ⭐⭐ |

| Value Stream Mapping | Moderate – requires detailed process analysis 🔄🔄 | Moderate – cross-functional participation ⚡⚡ | Visibility into process flow, identifies bottlenecks 📊📊 | Any process requiring flow optimization and waste identification | Clear process visibility, prioritization of improvements ⭐⭐ |

| Theory of Constraints (TOC) | Moderate – requires systems thinking and ongoing focus 🔄🔄 | Moderate – focused resources on constraints ⚡⚡ | Improved throughput and revenue, focused efforts 📊📊 | Processes constrained by bottlenecks needing throughput boosts | Focused improvement, throughput increase, prioritization ⭐⭐ |

| Statistical Process Control (SPC) | High – requires statistical skills and data analysis 🔄🔄🔄 | High – data collection systems and training ⚡⚡ | Process stability, early problem detection, defect reduction 📊📊 | Manufacturing and process industries needing control and stability | Early warning, quality improvement, predictive control ⭐⭐ |

Putting Your Improvement Plan into Action

You have now explored a powerful arsenal of business process improvement methods, from the waste-eliminating principles of Lean to the precision-focused DMAIC cycle of Six Sigma and the revolutionary change of Business Process Reengineering. Each methodology offers a unique lens through which to view and refine your operations. The common thread connecting them all is a commitment to moving beyond "the way we've always done it" and embracing a structured approach to creating more efficient, reliable, and customer-centric services.

For a service-based business like a plumbing company, a towing operation, or an HVAC service, these concepts are not just abstract theories. They are practical tools for survival and growth. A Kaizen event can fix a broken dispatching workflow, a Value Stream Map can reveal why it takes too long to get from a customer call to a paid invoice, and the Theory of Constraints can pinpoint that the single biggest bottleneck holding your business back is a constantly ringing phone that no one can answer.

Turning Knowledge into Actionable Results

The key takeaway is that you don't need to become a certified Six Sigma Black Belt or overhaul your entire company with BPR overnight. True, sustainable improvement begins with a single, deliberate step. The journey from a reactive, chaotic operation to a streamlined, efficient business is built on small, consistent wins.

Start by choosing just one of the business process improvement methods we've discussed. Don't get overwhelmed by the options. Pick the one that resonates most with a pressing problem you face right now.

- Is your team constantly scrambling and putting out fires? Start with Kaizen. Hold a small event focused on one recurring issue, like organizing the parts inventory in your service trucks.

- Are customer complaints about inconsistent service on the rise? Look to Total Quality Management (TQM). Get your team together to define what "quality service" means and how everyone can contribute.

- Do you feel like your resources are stretched thin and you can't get enough jobs done? Apply the Theory of Constraints (TOC). Identify the single biggest bottleneck, whether it's one person handling all scheduling or the time it takes to generate quotes.

The Most Critical First Step: Your Customer Intake Process

For the vast majority of emergency and on-demand service businesses, the most significant and often most overlooked bottleneck is the initial customer touchpoint: the phone call. Every missed call during a late-night lockout, a burst pipe emergency, or a roadside breakdown is a lost job and a direct hit to your bottom line. It's the ultimate constraint because if the customer can't reach you, none of your other process improvements matter.

This is where automation becomes your most powerful ally in business process improvement. By addressing this critical entry point, you create the stability and breathing room needed to tackle other operational challenges. An AI-powered phone assistant, for example, can instantly implement principles from several methodologies at once:

- It eliminates waste (Lean): The "waste" of missed calls and the time your skilled technicians spend answering basic questions is gone.

- It improves quality and consistency (TQM/Six Sigma): Every call is answered professionally and consistently, 24/7, ensuring a standard, high-quality customer experience.

- It removes the bottleneck (TOC): The phone system is no longer the chokepoint preventing growth. The AI can handle unlimited simultaneous calls, ensuring you never miss an opportunity.

Mastering these business process improvement methods is a journey, not a destination. It's about cultivating a mindset of continuous refinement. Start today. Pick one problem, choose one method, and involve your team. By fixing that first crucial process, you build the momentum to transform your entire operation, one efficient step at a time.

Ready to tackle the biggest bottleneck in your service business? See how Marlie Ai can automate your call handling, book jobs 24/7, and free you up to implement wider business process improvements. Visit Marlie Ai to see how our AI phone assistant can eliminate missed calls and help you grow your business.