Imagine trying to run an airline's ground crew using nothing but phone calls and paper notes. The chaos would be immediate. That's exactly what managing a field service team without modern tools feels like. Field service automation (FSA) is the digital command center that swaps out that chaos for a smooth, intelligent workflow for your mobile teams.

What Is Field Service Automation

Think of field service automation as a strategic shift—moving from constantly reacting to problems to proactively coordinating your entire operation. It's so much more than just digitizing your old paperwork. It’s about using technology to connect every moving part of your service business in real-time, making sure the right tech with the right skills gets to the right job at the right time. Every single time.

It's truly the backbone of any modern service business, and the market growth tells the story. The global field force automation market hit a value of about $3.51 billion in 2024 and is expected to rocket to $10.88 billion by 2032. That’s a compound annual growth rate (CAGR) of 15.4%, which signals a massive industry-wide change in how service companies operate. You can dig into more of this data on Fortune Business Insights.

From Manual Chaos to Automated Control

Before automation, a simple service call can trigger a storm of disconnected tasks. A customer calls, a dispatcher starts manually digging through schedules to find a free technician, scribbles down job details, and then calls the tech. That tech then has to write down the same info on a physical work order. It's slow, full of potential for human error, and gives the business owner zero real-time visibility.

Field service automation flips this entire script. It creates a connected ecosystem where information flows instantly and accurately between the customer, the office, and the technician out in the field.

At its heart, field service automation is about eliminating friction. It gets rid of the delays, miscommunications, and guesswork that bleed time, money, and customer trust. It turns a clunky series of manual handoffs into a single, fluid motion.

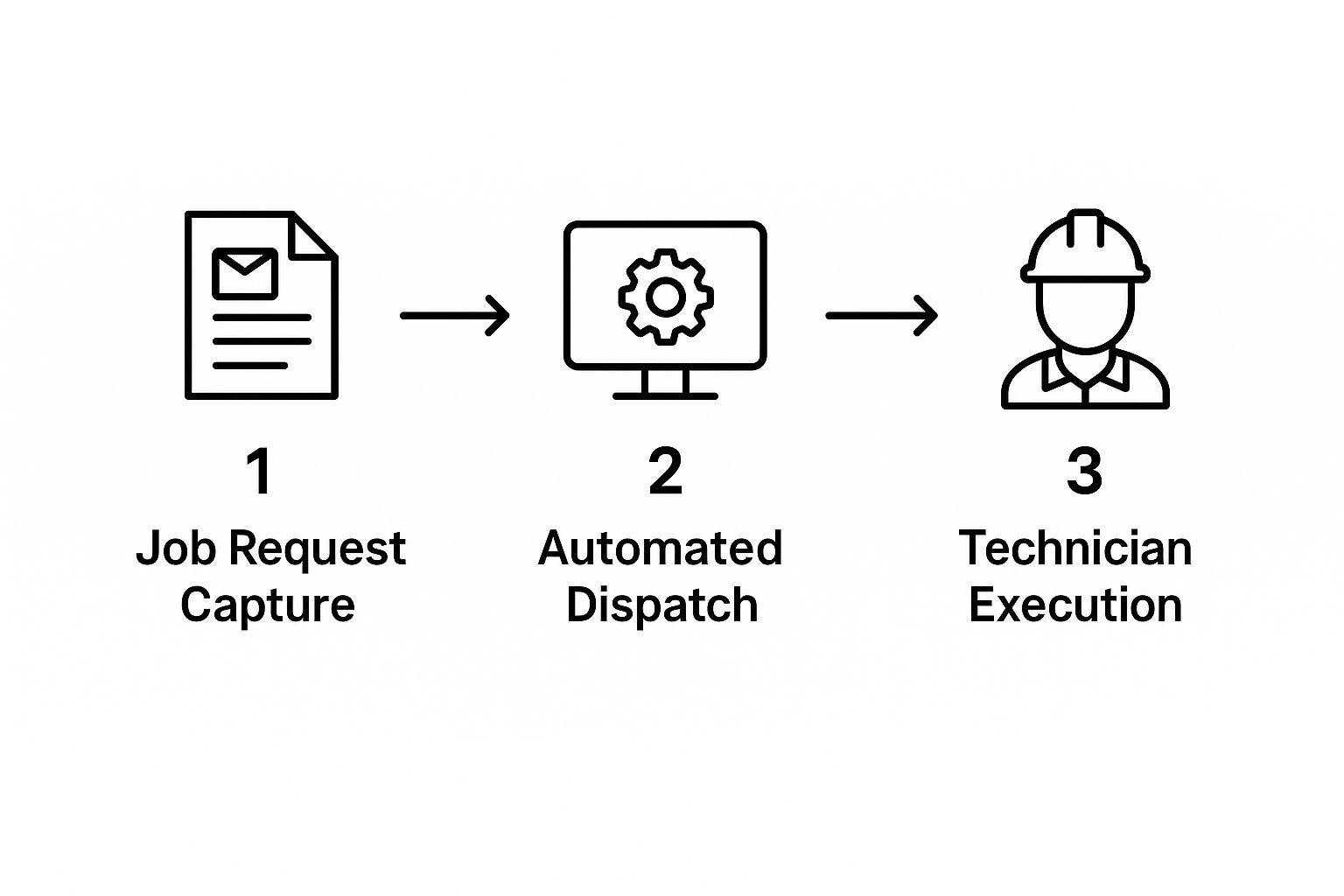

This visual shows the basic flow, from the moment a job comes in to the final fix by the technician.

As you can see, automation doesn't just pass along a request. It captures the job, intelligently dispatches the best possible resource, and gives that technician everything they need for a first-time fix—all inside one integrated system.

The difference between the old way and the new way is stark. This table breaks down exactly how automation changes the game across key operational areas.

Manual vs Automated Field Service Operations

| Operational Area | Manual Process (Without Automation) | Automated Process (With FSA) |

|---|---|---|

| Scheduling & Dispatch | A dispatcher manually checks schedules and calls technicians. It's slow, and based on guesswork about availability and location. | The system automatically suggests the best tech based on skills, location, and schedule. Dispatch happens in seconds. |

| Work Orders | Paper-based work orders are filled out by hand, often leading to lost paperwork, illegible notes, and data entry errors back at the office. | Digital work orders are sent to a tech's mobile device, complete with customer history, asset details, and checklists. All data is captured cleanly. |

| Communication | Constant back-and-forth phone calls and texts between dispatch, techs, and customers to coordinate and provide updates. | Centralized communication within a single app. Customers receive automated status updates (e.g., "Your tech is on the way"). |

| Invoicing & Payments | Invoicing is delayed until the tech returns to the office with paperwork. This slows down cash flow and requires manual data entry. | Invoices can be generated and sent from the field as soon as the job is done. Technicians can even collect payment on-site. |

| Reporting & Analytics | Gathering data is a painful, manual process of sifting through paper records. It’s nearly impossible to get an accurate, real-time view of performance. | Dashboards provide instant insights into job profitability, technician performance, first-time fix rates, and other key metrics. |

This comparison makes it clear: automation isn't just a minor upgrade. It’s a fundamental overhaul of how work gets done, leading to massive gains in efficiency, accuracy, and overall business intelligence.

The Key Operational Shift

The ultimate goal here is to get out of a state of constant reaction and into one of proactive management. Instead of putting out fires all day, you start preventing them.

Here's how that shift plays out:

- From Guesswork to Data-Driven Decisions: Instead of hoping someone is available, the system knows instantly based on live location data, skill sets, and schedules.

- From Paper Trails to Digital Records: Job details, customer history, parts used, and invoices are all managed digitally. They're secure, searchable, and accessible from anywhere.

- From Reactive Repairs to Proactive Maintenance: For recurring work, like quarterly fire extinguisher inspections or monthly filter changes, automation generates work orders automatically. This ensures you never miss a contractual obligation or service level agreement (SLA).

This kind of structured, intelligent approach is precisely why FSA has moved from a "nice-to-have" to an absolute necessity for any service business looking to grow.

The Core Components of an Automation Platform

A powerful field service automation platform isn’t a single piece of software. It’s more like a suite of interconnected components all working in harmony. A good way to think about it is less like a simple tool and more like a car's engine, where every part has a distinct but crucial role in propelling your business forward. Let's pop the hood and see how this engine transforms day-to-day operations.

The rapid adoption of these tools is fueling some serious market growth. The field service management (FSM) market—which is all about dispatching people to remote locations—was valued at USD 5.40 billion in 2024. But projections show it soaring to USD 17.29 billion by 2033, which reflects a strong compound annual growth rate of 13.8%. If you're a numbers person, you can dig deeper into this trend and its drivers in Straits Research's market analysis.

Intelligent Scheduling and Dispatching

At the very core of any great automation platform is its brain: the intelligent scheduling and dispatching module. This is so much more than just looking at a calendar to find an open slot. A modern system acts like an expert logistics coordinator, instantly analyzing a ton of variables to find the perfect match for every single job.

This automated process considers things like:

- Technician Skills: Does this job need a master electrician or is a junior apprentice fine? The system knows and assigns the right person.

- Real-Time Location: It uses GPS to pinpoint the closest available technician, which drastically cuts down on travel time and fuel costs.

- Job Priority: An emergency water heater failure is automatically pushed to the front of the line, ahead of a routine maintenance check.

- Traffic and Route Optimization: The software checks current traffic conditions to map out the most efficient route, making sure techs show up on time.

This isn't just about moving faster; it's about making the smartest possible assignment every time, without human bias or guesswork getting in the way.

Mobile Workforce Empowerment

The "field" in field service is where the real work happens, and automation essentially puts a mobile command center into every technician's hands. Through a dedicated mobile app, technicians get instant access to everything they need to nail the job on the first visit.

A mobile workforce app transforms a technician's smartphone from a simple communication device into a powerful tool for service delivery. It bridges the gap between the field and the back office, eliminating information silos and empowering techs with data-driven confidence.

Instead of showing up with a vague paper work order, a technician can pull up the customer's complete service history, access equipment manuals, view schematics, and check for parts—all before they even ring the doorbell.

Automated Work Order Management

Let's be honest: paperwork is the enemy of efficiency. Field service automation gets rid of it by digitizing the entire work order lifecycle. A job is created in the system, zapped over to a technician's device, and updated in real-time as they make progress.

This digital workflow gives you a few major wins:

- Eliminates Data Entry Errors: Information is captured once, correctly, and flows automatically through the system. No more sloppy handwriting or typos.

- Creates an Instant Audit Trail: Every single action—from arrival time to parts used and customer signature—is time-stamped and recorded.

- Accelerates Billing Cycles: The moment a job is marked "complete," the system can automatically generate and email an invoice, which dramatically improves cash flow.

Think about a hospital that needs quarterly fire extinguisher recharges and monthly filter replacements for its dialysis machines. An automation platform can be set up with an agreement that automatically creates these distinct work orders on the right schedule. Critical maintenance never gets missed, and compliance is a breeze.

Inventory and Parts Management

Nothing frustrates a customer more—or kills your profit margins faster—than a technician who has to leave to get a part. An integrated inventory management system tackles this expensive problem head-on by tracking parts availability across warehouses and service vans in real-time.

When a job gets scheduled, the platform can automatically check if the assigned tech has the right parts in their van. If not, it flags the issue. This gives the tech a heads-up to swing by the depot and grab what they need before heading to the customer's site. This one simple check is a massive driver of first-time fix rates, preventing wasted trips and keeping customers happy.

Key Business Benefits of Adopting Automation

Putting new technology to work is always a big decision. So, beyond the fancy features, what does field service automation actually do for your business? The answer comes down to real, measurable gains in how much you get done, how much you make, and how happy your customers are. This isn't just about looking modern; it's a direct investment with a clear and powerful return.

Automation changes how work gets done, which has a direct line to your bottom line. By figuring out the best routes, cutting out administrative busywork, and making communication seamless, your technicians can simply do more. The impact is huge—studies show automation can spark a 23% increase in workforce productivity. That translates directly into more completed jobs per technician, every single day.

The financial upside is just as strong. Industry experts estimate that adopting this technology can lift sales by 30% and cut sales management time by 14%. These aren't just numbers; they show how making your operations smarter fuels real business growth.

Drive Higher Productivity and Profitability

One of the first things you'll notice with field service automation is a massive jump in efficiency. Just think about all the time that evaporates into manual scheduling, travel, and paperwork. Automation gets that time back.

- Smarter Dispatching: Instead of a dispatcher guessing who’s closest, the system knows. It looks at real-time location data to send the nearest available technician, drastically cutting down on fuel and unpaid drive time.

- More Jobs Per Day: When travel time shrinks and admin tasks disappear, technicians can fit more paying jobs into their day. Even one extra job per tech, per day, adds up to a huge boost in annual revenue.

- Reduced Administrative Overhead: Automation gets rid of hours of manual data entry, filing, and follow-up calls. This frees your office staff to focus on things that really matter, like customer service and growing the business.

The ripple effect of these efficiencies is profound. It builds a leaner, more profitable operation from the ground up.

Elevate the Customer Experience

In the service world, customer satisfaction is everything. Field service automation is one of the best tools for improving it because it makes you more reliable and transparent. A critical metric here is the first-time fix rate—solving the problem on the very first visit.

Automation directly helps with this by making sure technicians show up with the right parts and the full story on the customer's service history. When you fix something on the first try, you avoid expensive repeat visits. More importantly, you earn a customer's trust.

A great customer experience isn't an accident; it's the result of a well-run operation. Automation provides the structure needed to deliver consistent, professional, and reliable service that keeps customers coming back.

Automated systems can also send customers real-time updates, like "Your technician is 30 minutes away," often with a live tracking link. This simple act of communication gets rid of those frustrating waiting windows and shows you respect their time. This is the kind of service that separates a good company from a great one, and it's just one of many business process automation benefits that shape how customers see your brand.

Quantify Your Cost Savings

Finally, let's talk about cost savings—the kind you can actually see and track. Automation isn't just another expense; it's an investment that pays for itself by plugging the financial leaks all over your business.

Think about these direct savings:

- Lower Fuel Costs: Better routes mean less time on the road and less money spent at the pump. Simple as that.

- Elimination of Paper: The costs of paper, printing, and storing stacks of physical records just vanish.

- Reduced Errors: By killing off manual data entry, you sidestep costly billing mistakes and disputes that can hurt customer relationships and hold up payments.

By making your team more productive, your customers more loyal, and your operations leaner, field service automation delivers a clear and measurable return on investment that makes your business stronger for the long haul.

Field Service Automation in Action

Theory and features are one thing, but the real magic of field service automation happens when you see it solve actual, tangible business problems. That’s when the benefits become concrete and you can really see what’s possible. Across all sorts of industries, companies are using automation to finally get a handle on challenges that have plagued them for years, and the results are hitting their bottom line.

This isn't just a niche trend; it's part of a huge shift. The global field service management (FSM) market, valued at around USD 4.68 billion in 2024, is set to explode. Projections show it growing at a blistering 16.0% CAGR from 2025 to 2034, mostly because businesses are hungry for mobile and cloud-based tools like these. You can dig into the numbers in the full market share analysis.

Let's look at a few specific examples that show this tech doing what it does best.

HVAC Emergency Response Transformed

Picture an HVAC company that built its whole reputation on being there, fast, during emergencies. Their biggest headache? The chaotic, manual scramble to dispatch technicians during a brutal heatwave or a sudden cold snap. The phone rings off the hook, and a dispatcher is left guessing which tech is closest and available, leading to agonizing delays and unhappy customers.

The Challenge: Slow emergency response times because dispatching was manual and they had zero real-time visibility into where their technicians were.

The Solution: They switched on a field service automation platform with smart, GPS-based dispatching. The moment an urgent call came in for a busted furnace, the system instantly found the nearest certified technician with an open slot in their schedule.

The Impact: The company sliced its average emergency response time in half. This didn't just make customers happier; it allowed them to tackle more of those profitable emergency jobs during peak seasons, giving their revenue a serious boost.

Medical Equipment Compliance Made Simple

Now, let's think about a company that services and maintains critical medical equipment in hospitals. For them, a missed maintenance check isn't just an inconvenience—it's a major compliance risk that could endanger patient safety. They were drowning in paperwork, trying to track complex service schedules for thousands of devices scattered across dozens of locations.

When you're dealing with life-saving equipment, there’s no room for error. Field service automation creates a digital safety net, ensuring that critical maintenance happens exactly when it's supposed to, every single time. It builds an unbreakable chain of accountability.

The Challenge: Keeping up with strict service level agreements (SLAs) and making sure essential medical devices never missed a maintenance window.

The Solution: The provider used the "agreements" feature in their FSA software. They set up automated, recurring work orders for every single piece of equipment based on its unique maintenance needs—like a quarterly check for one machine and a monthly one for another.

The Impact: Within six months, they hit 100% on-time service compliance. This completely eliminated the risk of regulatory fines, strengthened trust with their healthcare clients, and gave them a perfect digital audit trail for every single service call. To see how this fits into a broader strategy, check out our guide on essential field service management best practices.

Telecom First-Time Fix Rates Soar

Finally, consider a major telecom provider. Their biggest pain point was a frustratingly low first-time fix rate. Technicians kept showing up at a customer’s house only to realize they didn't have the right part or a clear picture of the person's service history. This meant expensive, reputation-damaging second visits.

The Challenge: A low first-time fix rate was burning through resources, driving up operational costs, and leaving a trail of unhappy customers.

The Solution: They gave every technician a mobile app linked to their central automation platform. Before even walking up to the door, a tech could pull up the complete customer history, read past service notes, and access digital diagnostic guides for the specific equipment on-site. The system even cross-referenced the job's needs with the parts stocked in their van.

The Impact: The provider jacked up its first-time fix rate by over 30%. That one metric sent positive ripples through the entire organization, slashing operational costs, improving technician productivity, and sending their customer satisfaction scores through the roof.

These stories show that field service automation isn't just another piece of software; it's a strategic move for any company that wants to deliver world-class service.

How to Implement Field Service Automation

Bringing new technology into your operations can feel like a massive project, but rolling out field service automation successfully is completely within reach if you have a solid game plan. This isn't about flipping a switch and hoping for the best; it's a strategic process. Think of this as a practical roadmap for getting automation into your organization smoothly and, most importantly, effectively.

The journey doesn't start with software demos or fancy sales pitches. It starts with an honest, hard look at how you operate right now.

First, a Thorough Process Audit

Before you even think about looking at software, you have to get crystal clear on what problems you’re actually trying to solve. What's broken? What's frustrating your team? What's costing you money? The first step is a deep audit of your current workflows.

Map out the entire life of a service call, from the moment the phone rings to the moment you get paid.

- Job Intake: How do you capture jobs now? Is it a chaotic mess of sticky notes and frantic phone calls? A clunky spreadsheet that’s always out of date?

- Scheduling and Dispatch: How does a job get assigned to a technician? Is it based on gut feelings, or a time-consuming manual shuffle of calendars?

- Field Execution: What roadblocks do your techs hit on-site? Are they showing up without the right parts or customer history?

- Invoicing and Reporting: How long does it take to bill a customer after the work is done? And can you even get to your data to see how your business is performing?

By identifying your biggest pain points, you’re creating a shopping list—a clear set of requirements that any automation software must address. This audit is the bedrock for every decision you'll make from here on out.

Select the Right Software Partner

Now that you know exactly what you need, you can start looking at software providers. But think of this as choosing a partner, not just buying a product. The market is packed with options, and it’s easy to get overwhelmed. Cloud-based platforms are gaining serious ground because they’re flexible and can adapt to your needs as you grow.

When you're weighing your options, zero in on these critical factors:

- Integration Capabilities: The software absolutely must play nice with the tools you already use, like your accounting or CRM systems. A new platform that traps your data in a silo just creates more problems than it solves.

- Scalability: Pick a solution that can grow with you. Will it handle more technicians, more job types, and more locations as your business expands? Don't pick a tool for the business you have today; pick one for the business you want to be.

- User-Friendliness: The most feature-packed software on the planet is worthless if your team hates using it. Look for an intuitive, clean interface—especially for the mobile app your techs will be using in the field every single day.

Your goal is to find a solution that feels like a natural extension of your business, not some clunky, forced add-on. The best partners will understand your industry's specific quirks and have built a platform to tackle them head-on.

Master the Human Side of Implementation

Technology is only half the equation. The other, arguably more important, half is your people. How you manage the transition for your team will make or break your implementation. This is all about change management.

Get your team on board from the very beginning. Don't just announce a new system; explain the "why" behind it. Show them how it's going to make their lives easier—less paperwork, fewer return trips for forgotten parts, and clearer communication with the office. Highlighting these direct wins is a core principle behind successful business process automation tools and strategies.

Next, invest in real, hands-on training. This isn’t about showing them which buttons to click. It’s about running through real-world scenarios that demonstrate how the new software fixes their old frustrations. Offer plenty of support after you go live—this isn't a one-and-done event.

Finally, you need to track your progress with clear metrics. Let’s make this concrete with a simple checklist to guide you through the process.

Implementation Phase Checklist

This table breaks down the critical steps for a successful implementation, helping you stay on track from selection to full adoption.

| Phase | Key Action | Success Metric |

|---|---|---|

| 1. Discovery & Audit | Map current workflows and identify the top 3-5 bottlenecks. | A documented list of pain points and required features. |

| 2. Vendor Selection | Demo at least 3 platforms; check references from similar companies. | A signed contract with a partner that meets all key requirements. |

| 3. Pre-Launch | Get buy-in from key team members and design a training program. | >90% of the team completes training before go-live. |

| 4. Go-Live | Launch the new system with dedicated support for the first few weeks. | A smooth rollout with minimal disruption to daily operations. |

| 5. Post-Launch | Monitor KPIs like first-time fix rate and travel time. | A 15% or more improvement in a key metric within 90 days. |

By using Key Performance Indicators (KPIs) like first-time fix rate, average travel time per job, and invoice-to-payment speed, you can prove the ROI and keep everyone focused on the goals long after the initial excitement wears off.

The Future of Field Service with AI and IoT

As powerful as field service automation is today, we're really just scratching the surface. What we're seeing now is a fundamental shift in the entire industry, moving beyond simple efficiency tweaks and into a world where service is truly predictive, sometimes even self-healing. This next wave is all about the powerful marriage of Artificial Intelligence (AI) and the Internet of Things (IoT).

This combination is flipping the old service model on its head. Instead of waiting for a frantic call about a broken machine, businesses can now see failures coming before they ever happen. This is the heart of predictive maintenance, and it’s a genuine game-changer.

From Reactive Repairs to Predictive Service

Think about an HVAC unit on a commercial rooftop. For decades, the only time you heard about it was when it conked out on the hottest day of the year, creating an emergency.

Now, imagine that same unit is fitted with a handful of IoT sensors. These sensors are constantly chattering, reporting data on its performance—subtle shifts in vibration, temperature, and how much power it’s drawing. This isn’t just noise; it's a story.

AI algorithms listen to this constant stream of data, learning the machine's unique heartbeat and what "normal" looks like. The moment the AI spots a tiny anomaly—say, a slight increase in motor vibration that suggests a bearing is starting to wear down—it can automatically sound the alarm.

This isn't just about scheduling a repair faster. The system can create a work order, check schedules, assign the right technician, and make sure the correct replacement bearing is already in their van—all before the client even knows there’s a problem brewing.

This approach stops downtime in its tracks. It transforms a potential four-alarm fire into a routine, planned maintenance visit. It’s the ultimate form of customer care: solving problems your customer never even had to experience.

Empowering Technicians with New Tools

The future isn't just about smarter equipment; it’s about making the people who service it smarter, too. Augmented Reality (AR) is quickly becoming a go-to tool for field technicians. A junior tech, for example, can hold up a tablet to a complex piece of machinery and see digital instructions, schematics, or repair videos overlaid right onto their view of the real world.

This gives them real-time, on-the-job guidance, which is huge for boosting first-time fix rates and training up the entire workforce without pulling them out of the field.

Deeper IoT integration also means we're heading toward a world where equipment can practically manage its own service schedule. A smart commercial freezer could monitor its own refrigerant levels. If it detects a slow leak, it could automatically schedule a service call through its provider’s automation platform.

This level of connectivity creates a seamless, almost self-healing service ecosystem. It elevates your business from a simple repair service to a strategic partner invested in your clients' success.

Of course. Here is the rewritten section, crafted to sound like it was written by an experienced human expert.

The Practical Questions: Getting Real About Field Service Automation

Alright, let's talk brass tacks. Moving your operations over to a new system is a big deal, and it's completely normal to have some pointed questions about what it all really means for your budget, your team, and your existing software. I get these questions all the time from owners and managers.

So, let's cut through the noise and tackle the big three.

How Much Does Field Service Automation Cost?

There's no single sticker price. The cost is a bit like building a custom home—it all comes down to what you need. A simple setup for a small team can be surprisingly affordable, while a massive enterprise solution with every bell and whistle will naturally be a bigger investment.

Most providers work on a subscription basis, usually priced per user, per month. What you end up paying hinges on a few things:

- Number of Users: How many techs, dispatchers, and office staff need to be on the system?

- Feature Set: Are you looking for the basics like dispatch and scheduling, or do you need the whole suite with advanced inventory tracking and deep analytics?

- Integration Complexity: Hooking into a standard CRM like Salesforce is one thing. Connecting to that custom-built accounting software your uncle's cousin made back in '08? That’s going to take more work and will affect the cost.

How Long Does Implementation Take?

The timeline for getting up and running can vary quite a bit. A small, nimble team with clear-cut needs might be live in just a few weeks. It's totally possible. On the other hand, a large-scale deployment for a company with hundreds of technicians and complex integrations could take several months to dial in perfectly.

The secret to a fast, successful rollout? A phased approach. Don't try to boil the ocean. Start by automating your biggest one or two headaches first. Once you've nailed that, you can expand from there. This gets you seeing value faster and makes the whole transition much smoother for your team.

Will It Integrate with Our Current Software?

Absolutely. Modern field service platforms are built for this. The whole point is for them to become the central nervous system of your operation, not just another silo of information nobody can access. They use what are called APIs (Application Programming Interfaces) to talk to your other essential tools.

When this is set up correctly, you create a single source of truth for your entire business. For example, a technician closes out a job on their tablet, and that information can instantly zip over to your CRM to update the customer's history and simultaneously pop into your accounting software to generate an invoice. No more double-entry. That’s the goal.

Never miss another urgent call or lose a valuable job again. Marlie Ai provides a 24/7 AI-powered phone assistant that instantly answers every call, books jobs, and captures customer details, ensuring you secure every dollar. Learn more at https://www.marlie.ai.